Tequila is an agricultural product and blue agave the quintessence of its greatness. We make all effort to farm the best mature agaves to make our tequilas. Right maturity is paramount to quality, not only for the accumulation of sugars but because the plant starts a fundamental process at the right time of its maturation, producing necessary enzymes to break down the complex sugars to release an immense biochemical energy for its reproduction. The fructans in the agave are among the most complex sugars in any raw material - hence the complexity of tequila - but they are long chain structures which are hard to access. That is why we wait for each individual plant to start its own internal transformation of these complex sugars into mono and di-saccharides.

Being one of few producers who grow 100% their own agave, and understanding that each plant is an individual, we walk the fields selecting plant by plant for optimum maturity, harvesting exclusively Maduro and Pinto agaves. Once selected, we harvest using ‘Jima media’ leaving between 1.5 and 2 inches of penca where important flavor compounds reside. Because of this selection it can take us up to 2 years to entirely harvest each field, and once harvested, we will plant two cycles of other crops, especially legumes before planting agave again. These will restore the soil and its nutrients and the essential nitrogen.

In the maguey plants, the chronological age or size are less important than the physiological ripeness in order to recognize their maximum accumulation of reserve fructans, and at the same time, their lower content of saponins.

E. Fonseca

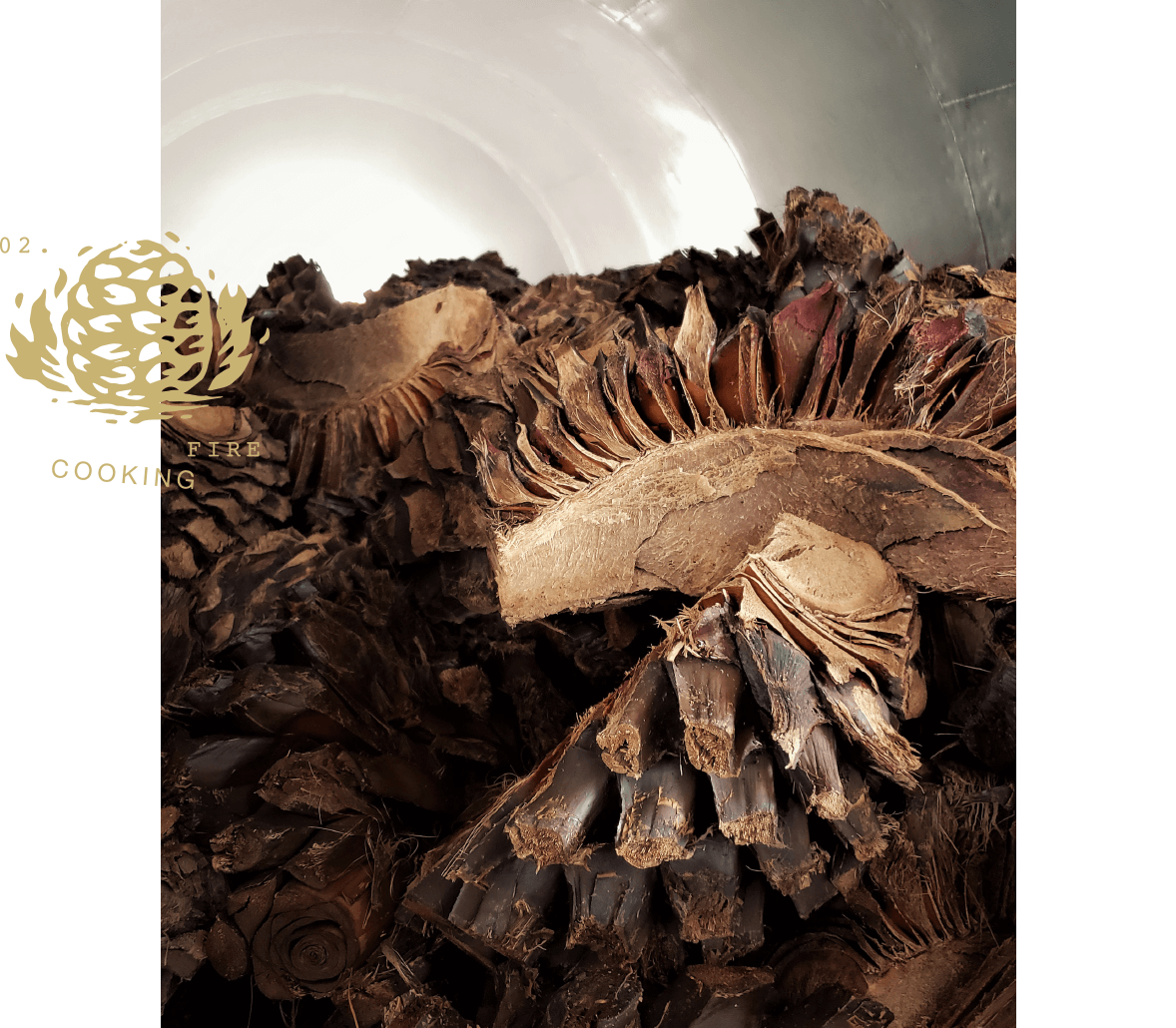

Once the selected blue agave piñas or hearts arrives to our distillery it is unloaded in the agave patio of La Tequileña. The ripe Maduro and Pinto agaves are halved or quartered depending on their size and carefully loaded and layered inside our steam hornos, where we slowly and carefully steam cook them at a low pressure between 24 and 32 hours. The previously dry and fibrous agave turns rich golden, moist and beautifully sweet. The aromas fill up the distillery when the hornos are opened. By slowly steaming the agave at a low pressure and then letting it rest for another 12 hours, we're going to continue the process of breaking down the complex sugars into mono and Disaccharides, which the plant itself had already started in the fields. These simpler resulting sugars are now accessible and fermentable. The cooked agaves are unloaded on the opposite side of the hornos and is then sent in a conveyer belt to our self-engineered Screwpress where the agave juice or aguamiel (honey-water) is going to be squeezed gently out of the fibers.

Fermentation is the heart of the tequila-making process and yeast is the key player. It’s also where one has least control; once fermentation starts, one can only hope for the best. That is why we make sure our agaves are fully ripe when they arrive and undergo a slow cooking and a gentle extraction. Fermentation is the biological action by which the complex sugars and compounds of cooked agave juice or aguamiel are transformed into alcohols, carbon dioxide and a great myriad of flavors and aromas. At La Tequileña we fill our open fermentation tanks with the aguamiel and, in some cases we also include the bagasse or agave fibers. At the same time, we propagate the yeast out of the same mature agave to make a concentration of it which is then blended proportionally with the mosto in the fermentation tanks.

By having selected our agave for optimum maturity, ensuring that the necessary enzymes are present, our fermentations are going to be completely natural without addition of any accelerants or external nutrients. Depending on the time of year, humidity and weather conditions, our fermentations are going to last between 3 to 6 days. The result is a low alcoholic wine between 6 and 9% alcohol by volume, with all the richness and complexity that will result in a great Tequila.

[Don Fulano uses approximately 30% of fermentations with bagasse or fibers and 70% fermentations without bagasse to create a product with mineral richness yet elegant.]

Contrary to fermentation, which is a biological process, distillation is a physical process. There is no organic life activity, but we are going to work with the components of the rich agave wine. By heating our copper stills using steam to a slow boil, we work the alchemy to produce a steady trickle of precious spirit, separating all its individual components to keep only its essence. For Don Fulano we're going to use a combination of distillation techniques to achieve the depth and character of the products that were looking for.

A double distillation in copper alembics to create a rich, deeper artisanal product which will constitute between 80 and 85% of the final blend, while a distillation in a double column copper Coffey still is going to create a delicate product of beautiful elegance, which will balance the profile, accounting for between 15 and 20% of the final blend. The use of copper is key to eliminates Sulphur based compounds and achieving a spirit of utmost purity and character.

About 95% of all aged tequila produced is matured in ex bourbon white American oak casks. Bourbon producer can only use their casks once by norm, so for distillers in Mexico, and pretty much everywhere these days, these are the easiest cask to get ahold off. However, the style of bourbon calls for heavily burnt casks that can easily overshadow the subtle nuances and delicate notes of the agave and its terroir within few years of aging. For that reason we were the first tequileros to explore using other kinds of casks.

Don Fulano is aged exclusively in ex-wine European dark oaks, primarily French limousine and Nevers which previously held wines from Burgundy, Bordeaux, and the Loire Valley in France, as well as other European oaks from Spain and eastern Europe, which allow us to go much deeper into aging, getting all the complexities that the process of maturation brings, without losing the essence of our spirit and its terroir. We also use multiple maturation locations at different altitudes, under different climates and cellar characteristics to gain deeper complexity, allowing us to blend in ways never before seen in tequila production.

Blending or vatting is quite common in Scotch, Cognac and in many wines but not in Tequila. By marrying products of different styles, we look to enrich and define the final product. Don Fulano is one of the few tequilas that uses a complex aging program and blending process. Each expression of Don Fulano parts from a map of character which defines the region where the agave comes from, the altitude and kind of soil, the time of harvest, fermentations with or without bagasse, distillation techniques and aging, including time spent and type of barrel used. By finding products within our library of tequilas that meet the characteristics of each expression, we can form the base of each new batch.

But having such base is just the beginning of an exciting process of triangular tastings where a panel will taste such base along with previous reference batches of the same expression, blending different style of tequilas from our library to complement the fruit, vegetal, mineral, spice, citrus and floral elements of the final product. Once the tasting panel defines a product it is ensembled in the vatting room and left to marry between 3 to 6 months, before being bottled using a simple cellulose filtration, 100% additive free.